|

TriTrack Air Drag Analysis

Investigation of the Flow About the TriTrack System

Amanda Kelly

Aaron Hamblin

Amanda Babcock

John Burroughs

Valori Booth

Fluids Lab ASE 120K

With Dr. David Goldstein

12/05/03

Department of Aerospace Engineering and Engineering Mechanics

University of Texas at Austin

W. R. Woolrich Laboratories

Austin, TX 78712

| |

Airflow over a 1/12 scaled model of the proposed TriTrack

system was investigated in the W.R. Woolrich laboratories

to determine the nature of the flow about the system and to

the drag coefficient of the vehicle. Jerry Roane, the inventor

of TriTrack, proposed the testing to support claims with empirical

data to Austin’s Board of Transportation. The complete

TriTrack system includes the vehicle body, two axles, two

wheels, and a triangular track. To determine the nature of

the flow about the vehicle, flow visualization was performed

with visible smoke released into the airstream and tufts placed

on the surface of the TriTrack system. At approximately 3.05

m/s, the smoke showed that the flow remained attached to the

body for almost its entire length. At about 18.29 m/s, the

tufts on the vehicle body depicted attached flow for the majority

of the vehicle by remaining streamlined. Drag coefficients

for the various system configurations were determined with

a force balance. The drag coefficient of the vehicle with

the entire system in place was calculated to be 0.15. The

wind tunnel tests revealed a drag coefficient of 0.07 for

the vehicle body alone, which was in agreement with Mr. Roane's

estimate of 0.09. By analyzing the drag coefficients for every

configuration, the axles and wheels were found to account

for approximately half of the drag of the system.

|

Table of Contents

- Abstract

- Nomenclature and Abbreviations

- Introduction

- Theory

- Methods

- Equations

- Apparatus and Test Procedure

- Flow Visualization

- Drag Coefficient

- Results

- Flow Visualization

- Smoke Wire

- Tufts

- Coefficient of Drag Determination

- Sphere

- Vehicle

- Conclusions

- References

- Figures

| |

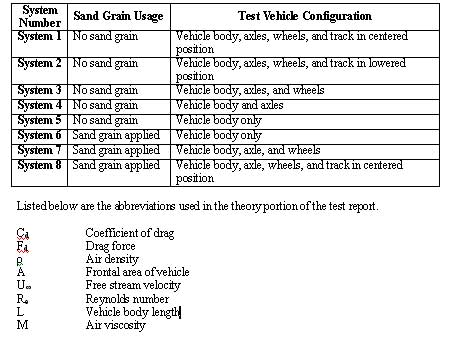

In Table 1 below a list is given of the nomenclature that

refers to each test vehicle configuration that was tested.

These system numbers will be used throughout the report.

Table 1 Description of System Configurations

| |

TriTrack is a monorail system proposed for the city of Austin

that has been in development since the 1973 Oil Embargo. A

local Austin inventor, Jerry Roane, has engineered the TriTrack

system to resolve several growing transportation concerns

for the general public. TriTrack is an electrically driven

vehicle that relieves the city of Austin of some of its dependence

on oil, an expensive natural resource that offers a limited

supply and produces dangerous byproducts to the environment.

The vehicle travels at about 37 mph on the residential streets

and about 180 mph on the monorail [1]. Collisions between

vehicles traveling above 37 mph have been shown to have a

high fatality rate, therefore, imposing this speed limit with

the TriTrack system will reduce road fatalities [1]. Clearance

between TriTrack vehicles on the monorail allows the vehicle

to safely accelerate to 180 mph. This system not only promotes

safety but it also provides the convenience of short travel

times.

The TriTrack vehicle body was selected carefully to be both

streamlined for efficiency and spacious for passengers. A

streamlined body, first designed in 1907, forces the air flow

to remain attached to the body, thereby eliminating the drag

associated with the air pressure that occurs in the wake behind

the separated flow [2]. The TriTrack vehicle is modeled after

the streamlined Class C Airship that has a body length to

diameter ratio of 4.62. Although ratios of 3.0 to 3.5 give

the smallest drag coefficients, a Class C Airship with the

ratio of 4.62 was proven by the Navy Aerodynamic Laboratory

in 1927 to have the lowest drag per unit volume [3], which

is essential for passengers.

Although the wind tunnel data taken in 1927

remains valid for the Class C Airship, slight differences

in the body design for the TriTrack vehicle warrant updated

wind tunnel tests. Jerry Roane fabricated a smoothed model

with high-end CAD equipment and machined it to within +/-

.05 mm of the data provided in the Navy’s report, making

a better model than the airship tested years ago. The TriTrack

vehicle also includes two axles and two wheels and excludes

a triangular section of the body where the railing will be

fitted. Another distinction between the two vehicles is that

the Navy's wind tunnel testing only went up to only

60 mph while the TriTrack vehicle is intended to travel at

180 mph.

Due to the deviation of the TriTrack model from

the Class C Airship, preliminary wind tunnel testing in the

W.R Woolrich Laboratories was necessary to get a better estimate

of the drag coefficient and flow behavior about the TriTrack

model. Because wind tunnel speeds are limited to 24.38 m/s

at the W.R Woolrich Laboratories, further testing will be

conducted at a later time at Pickle Laboratory to complement

the preliminary results.

| |

Flow visualization can be accomplished by the use of smoke

wire and tufts. The smoke wire is a visualization technique

that creates a sheet of smoke that passes over a test section.

The separation point of the flow is indicated by the point

where the smoke ceases to follow the contours of the body.

This wire is only effective for low speeds of 3.05 m/s or

less. Another technique of flow visualization is tufts, which

are short sections of twine attached to the body. The tufts

lay flat and smooth along the test article when subject to

laminar flow and are greatly disturbed in the presence of

turbulent flow. The point at which the tufts transition from

stable to disturbed is the separation point.

A force balance is a component used to measures

normal and tangential forces exerted on a body by aerodynamic

resistance. The forces can then be used to calculate lift

and drag coefficients. Sand grain can be applied to a vehicle

to force super-critical flow. Super-critical flow has turbulent

boundary layer that re-energizes the flow and causes the separation

point to move farther back on the body. The region of separated

flow has less contact with the body in super-critical flow,

which subsequently lowers the drag coefficient.

The Coefficient of Drag (Cd) is a dimensionless ratio of drag

force to dynamic force. It can be attained using the momentum

equation applied to the control volume of the wind tunnel

test section and assuming steady, incompressible flow. After

the drag force is found, the drag coefficient can be calculated

through the following equation:

The Reynolds Number (Re) for the vehicle can also be critical

to the results. It is a relation of the laminar to turbulent

transition point to the boundary layer thickness and skin

friction of the test article [2]. Re is dependent on the free

stream velocity. To better ensure the Reynolds Number obtained

is accurate sand grain is added to the nose of the vehicle.

When sand grain is applied to the nose, a Reynolds Number

is obtained that simulates a faster free stream. The vehicle

is designed to be traveling at speeds of up to 80.47 m/s but

the testing of the vehicle is done at a maximum free stream

velocity of 24.38 m/s. Reynolds Number equals:

| |

Flow visualization and data acquisition were performed in

the subsonic, open-test section wind tunnel at the University

of Texas at Austin. Several different configurations of the

experimental TriTrack vehicle and track were tested to determine

the nature of the flow around the system and the drag coefficient

of each configuration. The vehicle, provided by Jerry Roane

of Roane Inventions, was modeled after a Class C airship which

is the basic shape of a blimp. The body was machined from

billet aluminum measuring 0.44 m long with a maximum diameter

of 0.10 m located 0.16 m from the nose. Each of the two spun

aluminum wheels had an area of 4.23 x 10-4 m2 and each of

the two aluminum axles had an area of 3.58 x 10-4 m2. In order

to accommodate the triangular track, a 1.89 x 10-4 m2 triangular

sector was removed from the bottom of the vehicle.

The vehicle was mounted in the wind tunnel on a rear-mounted

sting. The track, supported by a platform, was positioned

under the vehicle as shown in Figure 1. Flow visualization

was first performed with a smoke wire at low flow speeds of

about 3.05 m/s. The flow was examined over the vehicle and

the wheels in system 1 to determine the exact separation point.

Smoke visualization was repeated for system 5 in order to

analyze the flow over only the vehicle body. The approximate

separation point of the flow around the vehicle in system

1 at higher flow speed was determined by observing tufts attached

to the vehicle, wheels and track. The behavior of the flow

near the track and vehicle junction was also examined with

the tufts. Tuft visualization was then repeated for system

5. Digital pictures were taken with a camera provided by the

Aerospace Engineering Learning Resource Center for both visualization

techniques.

The drag coefficients for several different configurations

were then calculated using the tangential force measurements

obtained from a force balance. In order to calibrate the force

balance, known tangential forces were applied to the sting

with a string and pulley assembly, as shown in Figure 2.

The axial force measured by the force balance was sent to a computer

with a data acquisition system. After calibrating the force

balance, a metal sphere with a diameter of 0.10 m was mounted

on the force balance and drag force measurements were taken

at various flow speeds. A drag coefficient for the sphere

was calculated from the drag force data and compared to known

values of drag coefficient to ensure the accuracy of the force

balance. The vehicle was then mounted on the force balance

and the track was placed directly beneath, but not contacting,

the vehicle. The track did not contact the vehicle so that

no loads were transmitted to the force balance by the track.

Twenty drag force measurements were taken at zero free stream

velocity to establish a zero force value. Twenty measurements

were then taken for increasing flow speeds between 3.05 m/s

and 24.38 m/s at 1.52 m/s intervals. For each flow speed,

the drag coefficient was calculated by dividing the average

of the drag force measurements at that flow speed by the frontal

area of the configuration. A plot of drag coefficient versus

free stream velocity was created to determine the drag coefficient

for that configuration. The same procedure was repeated for

systems 2 through 5 after removing the track, again after

removing the wheels, and for a fourth time after removing

the axles. Sand grain roughness was then applied to the maximum

diameter of the vehicle and the procedure was performed for

systems 6 through 8 to determine if forcing the flow over

the vehicle to become super critical would lower the drag

coefficient.

| |

Testing of the TriTrack was partitioned into two sections:

flow visualization and coefficient of drag determination.

Two techniques were used to visualize the flow about the TriTrack

test vehicle. A smoke wire created a vertical profile of the

flow about the test subject.

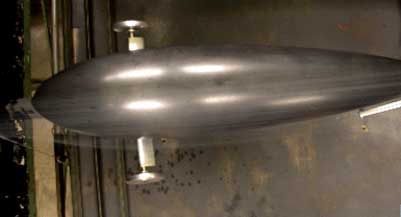

Flow was first tested over the TriTrack body placed atop the

triangular track. The smoke showed a very laminar flow over

the entire vehicle with minimal disturbances from the track.

The flow remained attached to the vehicle for almost the entire

length of the body. The attached flow as well as a clearly

defined stagnation point can be seen in Figure 3.

In order to visualize the flow about the TriTrack

wheels, the model was assembled into the system 1 configuration

shown in Figure 4 and the smoke wire was positioned

directly in front of the wheel position. Figure 4 shows

the flow about a wheel. The wake created behind the circular surface was

very minimal and could only be observed on the lower portion

of the wheel. A top view of the flow about a wheel is shown

in Figure 5. The symmetric airfoil shaped axles of

TriTrack proved to be a very aerodynamically smooth shape as presented

in Figure 6. The flow remained attached to the axle and

extremely little disturbance was seen at the trailing edge. Smoke

visualization from the top view for the system1 configuration, can be seen

in Figure 7. Flow was closely attached to the body and

any disturbed wake by the axles was not observable from this view.

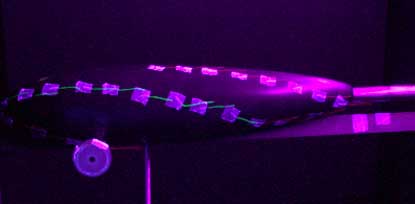

Tufts placed in a spiral pattern on the TriTrack body were

used for flow visualization at a free stream velocity of 18.29

m/s. The tufts in Figure 8 are straight and pointed

directly downstream. Static tufts are visual indicator of laminar flow

which agrees with the smoke visualization technique. Even

tufts placed on the top surface of the airfoil axle were stable.

Very slight disturbance was observed from the tuft placed

on the top of the wheel. The disturbance can best be seen

in the black lit image in Figure 9. A tuft wand was

used to try to determine a flow separation point but no disturbance

of tufts were observed over the entire structure. A view of

the tuft wand testing can be seen in Figure 10.

Utilizing the force balance, both the sphere and the vehicle

were tested for their average drag coefficients at varying

free stream velocities. For the vehicle, eight systems were

tested. The system configurations are described in Table 1.

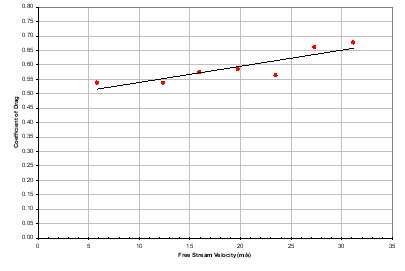

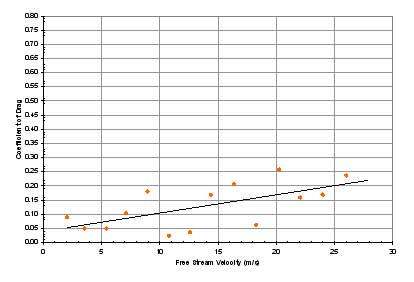

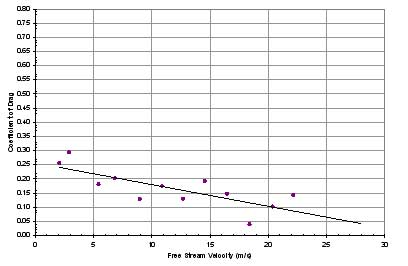

Figure 11 is a plot of the coefficient of drag

versus free stream velocity for the sphere. The trend line represents

an estimated average of the data. To obtain a better fitting

curve, the experimental high and low anomalies were discarded

in the calculation of the trend line. The average value from

this trend line is 0.57. White states that the accepted average

coefficient of drag for a sphere is 0.47 [4]. A plot of the

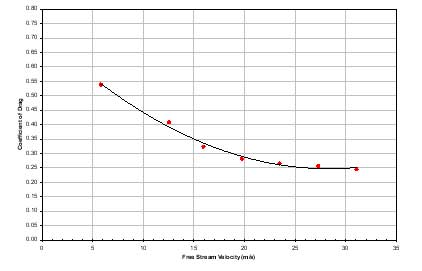

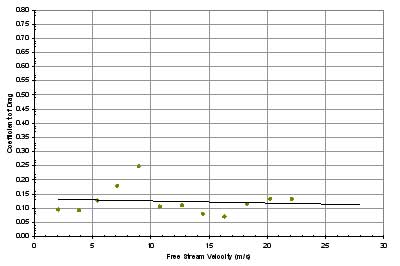

drag coefficient for the sphere with the addition of sand

grain is shown in Figure 12. The trend line from this

data set yields a rough average of 0.35. The addition of sand grain

lowered the average drag coefficient, confirming turbulent

flow transition. The accepted value of drag coefficient for

turbulent flow about a sphere is 0.20 [4]. The differences

between the calculated drag coefficients and the universally

accepted values confirmed the presence of sting drag.

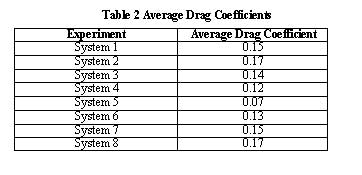

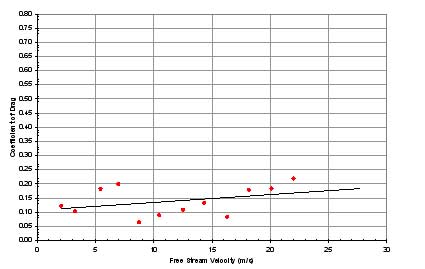

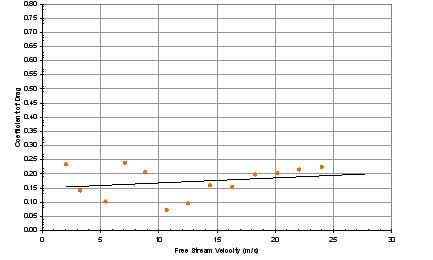

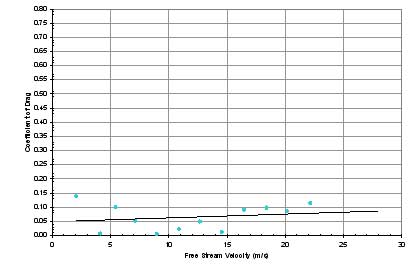

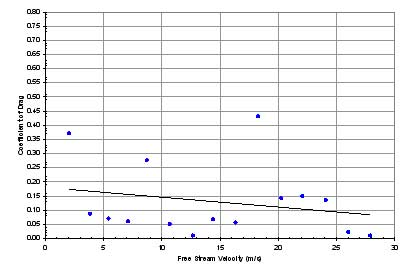

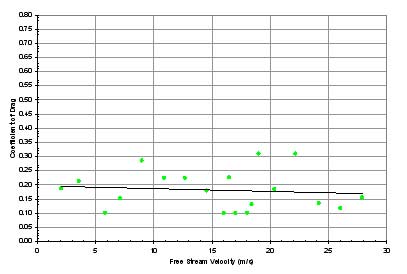

Figure 13 through Figure 20

are plots of drag coefficient versus free stream velocity for the data in

their respective experiments. Average values, taken from the trend lines for

each set of data, are shown for each system in the following

table.

In systems 1 through 5, two trends became apparent.

First, the drag coefficients were very low, nearing 0.10 on

average. Second, removing the wheels and axles significantly

lowered the average drag coefficient. With the loss of the

wheels in system 4 and the axles in system 5, the drag coefficient

dropped by half. With the addition of sand grain in systems

6 through 8, as shown in Figure 21, a turbulent

boundary layer was induced in an attempt to lower the vehicle's drag

coefficient. However, the sand grain seemed to raise the drag

coefficient on average. Parallel experiments of systems 5

and 6 saw an average drag coefficient increase of 0.05. Systems

3 and 7 showed an increase of 0.01, and systems 1 and 8 showed

a 0.02 increase. Another point of interest was the removal

of the track. Findings from track removal showed a uniform

decrease in the average estimated drag coefficient. The decreases

in the system changes from 8 to 7 and 1 to 3 were 0.01 and

0.03, respectively.

Finally, as observed in the sphere experiment,

there was sting drag present. Each drag coefficient in Table

2 would be higher than the measured value due to added drag

caused by the sting. Also, the wire used to support the weight

of the vehicle created a small amount of drag. Large variations

in the measurements taken due to force balance oscillation

observed at high free stream velocities render the drag of

the wire too small to affect our calculations.

| |

The results of the flow visualization showed laminar flow

across almost the entire vehicle, as expected from the research

conducted on the Class C airship. The triangular sector removed

from the vehicle for the track did not cause significant changes

in the flow, as expected. During calibration, the calculated

average coefficient of drag for the sphere was higher than

the nominal value due to drag force on the sting and calibration

errors. However, the values were similar enough to ensure

that the force balance was providing accurate data. The expected

drag coefficient for system 5 was 0.09 due to small differences

between the TriTrack vehicle and the Class C airship. The

measured drag coefficient for system 5 was 0.07, which was

close to the expected value. Some random errors may have resulted

from oscillation of the vehicle, which originated from motor-induced

tunnel vibration. Because flow about the vehicle without sand

grains stayed attached for almost the entire length of the

vehicle, forcing supercritical flow with sand grains did not

change the separation point enough to reduce an already negligible

pressure drag. In fact, when sand grains were applied to the

vehicle in systems 6 through 8, the coefficient of drag increased

because of the added friction drag from the sand. For system

3, the drag coefficient was found to be almost twice as large

as the drag coefficient for system 5, meaning that the wheels

and axles account for half of the drag of the vehicle. As

suggested by Mr. Roane, the performance of the TriTrack system

could be greatly improved if the wheels were retractable.

|

- Roane, Jerry, “TriTrack,” http://www.tritrack.net,

23 November 2003.

- Von Mises, R., Theory of Flight, Dover Publications, New

York, 1959, pp. 102.

- NACA, “Drag of C-class airship hulls of various fineness ratios,” http://naca.larc.nasa.gov/reports/1929/naca-report-291/naca-report-291.pdf, 26 November 2003.

- White, F., Fluid Mechanics, 5th ed., Avenues of Americas, New York, 2003, pp. 25, 314, 48

|

|

|